Knowing all of the innovations, including automation and robotics in 3PL, is very significant. Specialists therefore develop awesome automation innovations adapted to the individual requirements of delivery services. Decades of experience in the field of 3PL, help scientists accurately analyze individual parts of processes, complete material flows, and automate them using appropriate methods.

Try Onro for Free

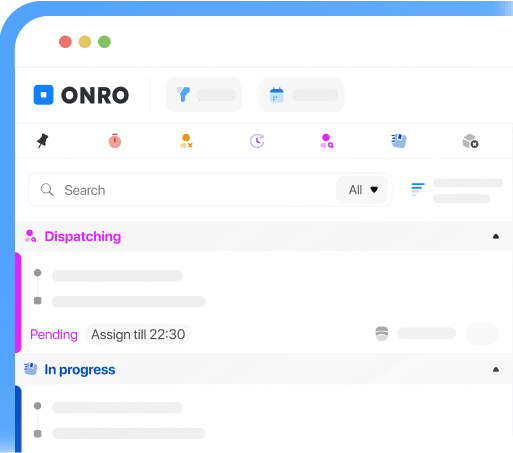

Get your free access to the Onro All-in-one 3PL Software.

Automation in 3PL

Based on the Cyzerg article, without the use of a WMS system by a 3PL operator to automate warehouse operations, it is impossible to effectively provide services to warehouse clients. For a 3PL operator, it is important to start working with the goods of each new client as quickly as possible. For this, the WMS solution must be flexible enough to quickly (from several hours to 3-5 days) carry out and change individual settings for each owner of goods, operations, and required reports.

A professional WMS must have comprehensive functionality to serve customers with different technological processes, using different storage systems, different transportation options, and different product groups: food, clothing, shoes, toys, FMCG, e-commerce, labeled goods, weights, etc.

Also, the WMS should have fairly simple and reliable functionality and solution development tools:

The ability to quickly reconfigure processes to meet requirements at the “tick” level. The ability to perform settings by configuring: additional setup of data exchange, billing system (invoicing), additional configuration of reports, and shipment labels.

The ability to rework processes and develop new processes. For example, a sorter conveyor appears at the operator’s new warehouse, and it is necessary to rework the reservation, selection and sorting processes to work in this mode: first, mass collection of orders (for example, 1-2 piece orders are collected in a separate flow), and then sorting.

AMR robots

The biggest optimists in terms of integrating AMR robots into logistics from a sector-specific perspective are automotive companies, with 88% of them considering implementation within the next two years.

Of the electrical engineering companies, 60% see the possibility of deployment within two years, and another 30% within three to five years. In the fast-moving consumer goods (FMCG) segment, 58% of businesses within two years, as well as independent logistics providers (3PLs).

The deployment of autonomous robots provides significant business benefits, from optimizing labor and operational costs to increasing productivity, delivery accuracy, and efficiency. Again, companies from the automotive sector see great potential, where 64% of companies consider the deployment of AMR technologies beneficial for overall costs, safety and quality.

Additionally, 16% of automotive businesses see AMR as a competitive advantage. In the case of the FMCG segment, even 79% see advantages in the areas of costs, safety and quality. On the other hand, 43% of electrical engineering companies and only 25% of 3PL forwarding providers are convinced of the same.

More than 50% of respondents from both automotive and freight forwarding stated that the biggest obstacle to advanced automation projects is the lack of qualified personnel. In the electro technical segment, 35% of respondents and 30% of respondents in the FMCG sector expressed their opinion in this way.

More than half of respondents from all industries also said that investment in their automation projects has a slow return on investment. In addition, almost 40% of FMCG and electrical companies claim that their processes are subject to frequent changes or are not large enough to be automated.

Using Software for Automating 3PL

Route planning is neither good nor bad until it is evaluated by results. For evaluation, we need maximum information about the actual course of the drive. From the tachograph, you can only read basic data about distance, speeds, and safety breaks. This is enough to detect the misdeeds of drivers, not to make a stable profit.

3PL Softwares like Onro with GPS tracking are dedicated to collecting data from trips. Not only do they show dispatchers where the vehicle is right now. The driver can also enter a lot of other information into the application. For example, consider the proof of delivery. Inaccurate estimates of delays at customer ramps can destroy the entire plan.

Vehicle tracking is also a driver behavior check. Careful evaluation of all knowledge from the field is crucial for a business with such an uncertain margin.

Onro team members are loyal to a proven and reliable brand that ranks among the greatest technological innovators of this century. Thanks to this, we are able to prepare an effective and functional solution for our 3PL logistics customers that will meet their needs and at the same time, take into account further development.

Conclusion

So, we learned that innovations in 3PL are essential. Implementation of a new innovation like AMR is often referred to as a technical or technological investment, although it is mainly about supporting delivery business processes.