On-time delivery (OTD) is the percentage of orders delivered according to schedule. This is an important KPI that measures customer satisfaction and loyalty. This post covers how improving OTD performance can enhance logistics efficiency and experience for the customer. Read on to know which key points can improve the OTD rate.

Try Onro for Free

Get your free access to the Onro All-in-one Delivery Management Software.

What Does On-Time Delivery Performance Metrics Mean?

On-time delivery (OTD) is a key performance indicator (KPI) indicate the percentage of orders that have been delivered on time. Typically, these act as a key indicator of fleet efficiency. The metrics then give insight into service levels as much as the accuracy of the time estimations and the logistical performance, as well.

One in five consumers reports that they would not forgive a brand for late delivery. Recent data highlights the impact of OTD on customer retention or repeat purchases.

The Importance of On-Time Delivery Metrics

A high on-time delivery rate signifies efficient logistics. A low OTD metric would indicate that an inefficient logistics system can frustrate customers and erode trust and longer customer retention. Such metrics also point out bottlenecks in the fulfillment and delivery process. Failure in performance mostly indicates something else going wrong under the surface in business and requires immediate attention.

How to Calculate Your On-Time Delivery Metrics

To calculate the On-time delivery rate, you should divide the number of all orders that are delivered on time and the number of delivered orders after the promised time.

An OTD is usually measured within a date range spanning five days prior to the delivery due date, for example: if the delivery is due by October 1, the OTD date range will be from September 27 to October 1 and everything arriving after October 1 would be considered late.

In fact, knowing the total number of deliveries for the appropriate period and how many of those made it onto the delayed list is just enough to get appropriate figures in the OTD calculator.

For example, in a case where you have 5 delayed deliveries for the week, and the total deliveries made that week are 100, then the OTD metric becomes 95%.

5 Reasons for Poor On-Time Delivery Metric

1. Inventory Management Issues

The inability to inventory can lead to the acceptance of stockout orders. This means that the delivery will be dependent on the time the business runs itself to fill it and has little chance of fulfilling the orders.

2. Inefficiencies in Order Fulfillment

Disorganization of products or lack of proper labeling and packaging thereby slows down dispatching orders.

3. Delivery Problems

Variable workload distribution among the delivery drivers can lead to missing delivery times over a given number of destinations due to poorly optimized routes or transit times exceeding the expected.

4. Non-Optimal Routes

Delay normally occurs in a range along the route. Efficiently planning routes can save much time on the road. Properly packing trucks and mapping out possible optimal routes along which deliveries can be made can help delay and bring timely deliveries.

5. No Visibility

Without tracking and the entire fulfillment process in real time, many companies are unable to meet their delivery deadlines. Most often misinterpretations or even insufficient tracking points in earlier stages in the life of the supply chain, such as warehouse handling or white-glove services, delay it. This leads to a lack of end-to-end visibility, where a delay is unable to be found and therefore a quick fix fails.

How to Improve On-Time Delivery Metrics and KPIs

Here are some ways to improve the results of the delivery.

1. Set an OTD Goal

Set up an internal goal for on-time delivery metric rates, and track performance on a scorecard. Offer employee motivations for meeting the internal target. Team incentives can boost performance up to 44%.

2. Interview Employees

Now hold talks with employees performing the actual physical delivery to find bottlenecks that slow their performance. You could find them to provide good insight on what process improvement will be adopted for such.

3. Increase Inventory Management

Invest in an inquiry management program that will help prevent stock-outs, but also keep your goods organized. Enterprise resource planning (ERP) software can completely streamline supply chain activities for better optimization.

4. Streamlining Order Picking

Leave behind single-order picking. Instead, start doing it by batching, zoning, or clustering picking to take less time looking for products. These alternative picking methods can drastically reduce fulfillment time.

5. Minimize Packaging

Among them is excessive packaging. Railing it down would immensely scale fulfillment timelines, where instead of having to pack parts into several boxes with no extensive protective wrapping, they all could fit into one box. It really improves the supply chain performance.

6. Increase Effectiveness with Routing Software

Onro is a route optimization software that will totally cover the itinerary of any delivery, not allowing the wasting nor duplicating promised mileage. It’s a system that optimizes the route schedules, balancing and distributing workloads of drivers in such a manner that evenly distributed deliveries are equitably assigned to the driver, resulting in better, more productive delivery times, delivering on time while minimizing idle time.

7. Set Clear On-Time Delivery Goals

It will include specific on-time delivery (OTD) goals for your shipments. Such metrics need to have scorecards to monitor, rewarding on-time drivers for hits.

8. Listen to Your Drivers

Talk to your driver about what happened to them, the delays, and the bottlenecks they have met while driving along routes. Speak with them to be able to plan their route with fleet management.

9. Communicate Clearly

Facilitating communication with suppliers, customers, and other stakeholders in the process. Set KPIs and definitions for similarity so that all will move fast with each other in emergencies or in cases requiring speedy change.

How Onro Boosted On-Time Delivery Metric KPI and Improved Customer Experience

Try Onro for Free

Get your free access to the Onro All-in-one Delivery Management Software.

A continuous visibility and automation process, optimizing dispatching and routing, connecting systems for transparency, real-time updates about the shipment’s journey for customer or client expectation management adjustments, and flexible cover backup, such as additional drivers or vehicles, are steps toward a successful high on-time delivery. You can track all these steps with Onro.

With Onro you can streamline the process for different users, ensuring seamless coordination among customers, drivers, dispatchers, and admins. Each user type has tailored features to meet their specific needs. This real-time tracking feature can boost on-time delivery metric KPI and increase customer satisfaction.

Well, let’s dive into each side of this coordination.

For Dispatcher

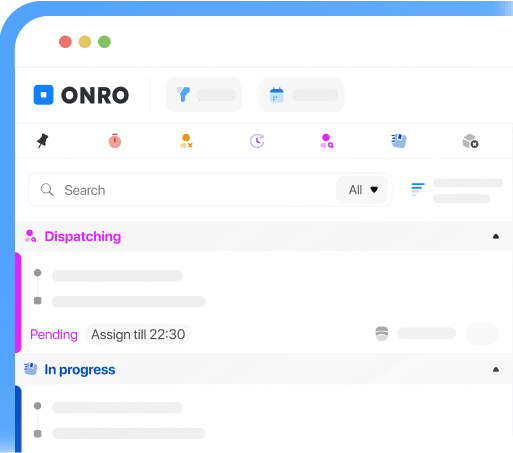

The intuitive features in the dispatcher panel make it possible to manage and track the orders. The processes that dispatchers can execute are as follows:

- Create or search orders using various filters.

- Real-time updating of orders.

- Readily available references to the order history for action.

- Real-time monitoring of the drivers.

For Admin

An Admin dashboard is where all important data and reporting tools for this effective tracking of orders and their delivery status lie. Admin can do the following:

- Generate reports using various filters to get to the required information in no time.

- Analysis and visualized the orders over a map for a better overview.

- Monitor and update necessary order statuses to avoid conflicts and at the same time, ensure smooth flow.

For Customer

The Customer App provides several benefits for order convenience that help a customer keep track of his order purchase process. Customers can:

- Make it easy to do multiple orders at once.

- Cancel orders before someone picks them up.

- Change their payment method per his wish.

For Driver

The role of the driver will be maximally defined by the driver app which makes it simple to assign or accept order schedules. The driver will have access to the following:

- Instantly receive, view, or accept orders.

- Coordinate with customers for communication to be smooth.

- Manage and update the status of their orders from start to end.

Conclusion

Regarding connections among resources, systems, orders, and drivers to create the environment for complete visibility and control of the whole process, an open, current, and connected platform will provide the best opportunity for on-time delivery.The Onro’s delivery management software automates and optimizes all of your last-mile logistics and fulfillment processes for speed, visibility, and analytics that affect making actionable decisions to improve your on-time delivery rate and customer satisfaction. Get Your Free Demo Now!

Try Onro for Free

Get your free access to the Onro All-in-one Delivery Management Software.