How do FMCG companies ensure that products reach consumers quickly and efficiently? The fast-moving consumer goods (FMCG) industry is based entirely on quick and effective logistics processes. It manages short life cycles, criteria for sudden changes in demand, and vast complexities in the supply chain. This post discusses important elements of FMCG logistics, such as key distribution challenges, technology integration, food delivery software and sustainable practices.

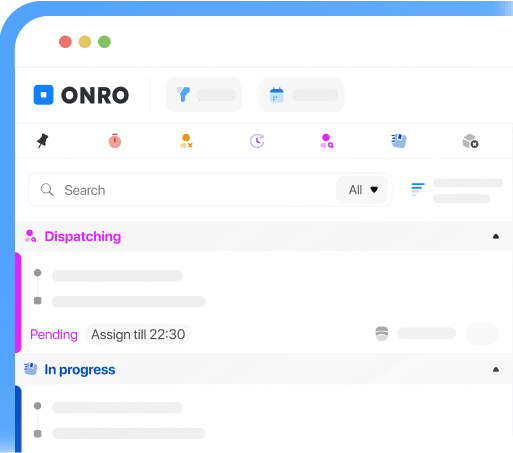

Try Onro for Free

Get your free access to the Onro Food Delivery Management Software.

What is the FMCG Industry?

Fast-moving consumer Goods (FMCG) are their abridged form because of their very short life cycle, considering their very high consumption. These are otherwise better known as consumer-packaged goods (CPG), highly perishable due to their good turnover rates and consistent production and sales in the retail or online markets.

FMCG Logistics products comprise many items for everyday use, including food items and beverages, beauty and cosmetic products, various cleaning, hygiene, and, at times, healthcare products, as well as paper and stationery. It also represents the seasonal setting of a product for sale in a given period, which, in turn, will fall under fast-moving consumer goods. This great grass net would include sectors like fashion and healthcare and extend to consumer electronics.

It is anticipated that by 2025, the global FMCG market will cross the figure of 15 trillion dollars, growing at the rate of 5.4% every subsequent year. However, a very defining feature in the FMCG market is the low cost of production of goods, which requires companies to streamline operations continuously. Companies must operate by optimizing production, storage, and distribution processes so that products can be offered at affordable prices while securing consumers’ demands.

Logistics Operations in the FMCG Logistics Industry

Speedy Logistics is the most important in the FMCG logistics sector, considering the very short shelf life of products and perishability factor. Processing orders and having quick access mainly match the needs of high customer demands. It poses a series of challenges, such as inventory management, security in storage, and lead times in compliance with stipulated eCommerce delivery management standards. The evolution of omnichannel logistics is the other that generates challenges in balancing sales through different sales channels with the lowering of logistics costs.

Thus, Most FMCG firms adopt and maintain warehouse management systems (WMS), which include real-time tracking visibility of inventories. These systems allow firms to exercise greater control and enable higher efficiencies in operations. Digital tools such as supply chain management (SCM) systems automate demand forecasting and sales planning, raising the stakes in performance on the overall agile supply chain.

Other demand-sided improvements come from the Internet of Things (IoT) that began revolutionizing product demand patterns, primarily in areas such as the home care market through automatic replenishment and how free consumers navigate the purchase journey- being increasingly free of seams.

FMCG Supply Chain Solutions Examples

In FMCG logistics, the need for advanced intralogistics technology is to propel productivity, ensure product traceability, and handle products with efficiency and safety.

Havi Logistics

Havi Logistics has implemented automated storage systems and warehouse management software at its new facility in Portugal, reducing manual movements and allowing for improved efficiencies not only in shelf-life but also in order management control.

Natura Bissé

Natura Bissé was able to optimize its production with a Mecalux-designed automated warehouse located in Spain. This new arrangement greatly increased operational flexibility to guarantee uninterrupted production while simultaneously reducing logistics costs by cutting out the need for outsourced facilities.

Takeda

Takeda, a Japanese pharmaceutical company operating in Poland, uses Interlake Mecalux’s EasyWMS to manage its automated warehouse with a capacity of over 6,500 pallets while ensuring full traceability of products and perfect execution of logistics processes, thus confirming the importance of digitizing processes to the FMCG sector.

The FMCG Logistics Industry Demands Efficient Logistics Processes

With this ever-increasing eCommerce hysteria and the importance of omnichannel strategy for delivery marketing service, the fate of increasing multiplexity in warehouse logistics is affecting FMCG. In terms of space and logistics, companies extend their warehouse and logistics modernization demand by investing in automated and ICT solutions, which smooth the movement and storage of goods.

Take an example of these enablers: Warehouse Management Systems (WMS). They add much value in enhancing controls over logistical operations and ensuring that more errors are mitigated within order processing, thereby promising timely deliveries. That way, systems ensure that channel operations speed up and reliability improves.

Competition Throughout the FMCG Supply Chain

The Role of Established Brands and Private Labels

FMCG logistics hence depends on their well-established brands and private labels manufactured by third parties and retail-housed under their names, in addition to surviving in maniac competition.

The Rise of New Retail Channels

New retail channels such as Direct-to-Consumer (DTC) and Amazon have made it easier for companies to bypass intermediaries, reach customers directly, and improve their penetration level. They also add to the circuitry that has to be understood and accepted.

Innovation and Differentiation

The most efficient of these supply chains is not by far all that this context is at innovation—differentiation in quality features and packaging also abouts a lot of the fire among consumer dynamics.

The Need for Adaptive Strategies

While many adaptations must be made to changing consumer and market trends, the changes have to be narrowly differentiated and competitive advantage-oriented. Companies would also need to gain this edge by responding as quickly as possible to changes in demand caused by promotions or seasonality.

Demand Volatility

The Impact of Market Fluctuations

Variations in demand caused by trends, global events, promotions, or seasons are very heavy on companies’ guessing statues, leading to overproduction, underproduction, and inefficiencies.

Challenges in Capacity Balancing

Capacity means that production can run smoothly without interruptions and avoid being smothered by unused capacity. Various elements, such as changes in raw material prices, political threats, and suppliers’ control over much-needed materials, change that.

Try Onro for Free

Get your free access to the Onro Food Delivery Management Software.

FMCG Logistics Supply Chain Challenges

Distribution Complexity

Managing transportation routes, inventory at different locations, and timely deliveries while balancing costs vis-a-vis service-levels is a very vital aspect of management by FMCGs.

Product Life Cycle Management

As the changes in consumer preference are rapid, the life of products from their birth to extinction induces various challenges. To ensure their relevance in the market, companies must adapt their products within a very short time frame.

Supply Chain Transparency

It becomes practically impossible to track products with the introduction of several third-party suppliers, manufacturers, and retailers. Transparency will thus lead to inefficiency and cost.

Environmental Sustainability

As environmental concerns become greater, FMCG companies face increasing scrutiny regarding reducing carbon footprints, encouraging sustainable packaging, and sourcing raw materials, among other things.

Regulatory Compliance

Ever-evolving aspects of regulatory environments, such as tariffs, trade restrictions, and environmental standards, add another aspect of complexity when dealing with many different countries of sourcing.

Technology Integration

Moving towards digitization and using demand sensing and WMS (Warehouse Management Systems) has been taken as a step towards productivity. However, integrating these across an aerosol-fragmented supply chain setup has its own story.

Conclusion

The most effective logistics in FMCG require a well-balanced mix of speed, cost, and flexibility. Companies should optimize their supply chains by relying on digital mechanisms, automation, and sound planning to stay ahead of the competition. As consumer demands are morphing, process innovations, transparent communications, and sustainable practices must become the order of the day if businesses want to meet market expectations and still make a profit.

For seamless last-mile delivery and optimized FMCG logistics, leverage Onro. Our advanced delivery management system enhances efficiency, reduces costs, and ensures fast, reliable deliveries to customers.

Get a free demo and take your FMCG logistics to the next level!

Try Onro for Free

Get your free access to the Onro Food Delivery Management Software.